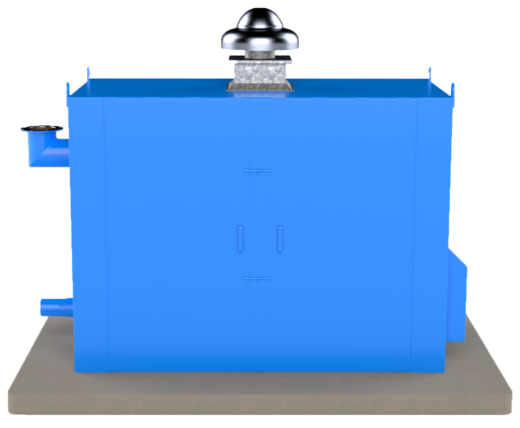

Hydrogen peroxide is the most popular bio-decontamination chemical used, but others including peracetic acid, chlorine dioxide and nitrogen dioxide are available or in development. The next evolution, of course, was to make larger airlocks. A number of suppliers now offer larger airlocks that act as standalone machines for transfer of materials in/out of rooms. Decontamination systems can also be integrated with actual airlocks and rooms in a facility, although HVAC systems must be designed for this.Ĭycle times in standalone material airlocks are dependent on the size of the chamber and the materials being decontaminated, but times ranging from 30-60 minutes are reasonable for most loads.

This development provided flexibility to streamline material transfers, especially for items such as environmental monitoring supplies, alcohol wipes and other items that cannot be steam sterilized in an RTP (Rapid Transfer Port) canister. Suppliers developed small airlocks with fast decontamination cycles to move items in and out as needed, with cycle times as low as 15-20 minutes. The evolution of isolators for aseptic processing has led to advancements in material airlocks for transferring materials in/out of an isolator. In recent years, new technology has provided a number of significant improvements to aseptic processing facilities. As we have seen during the IPS INTERPHEX tours the past couple of years, suppliers are introducing isolators with faster cycle times, high-speed filling machines with 100% IPC (In Process Checkweigh), single-use disposable systems and more. Until recently, transferring materials between rooms with different environmental classifications has not changed.

0 kommentar(er)

0 kommentar(er)